Newsroom

NUTEC Group – a busy week in Bavaria

April 23, 2024

Experience the future of ceramics with NUTEC Group at Ceramitec 2024. From Munich to the world, join the conversation on innovation and sustainability.

Customer Success Stories (CSS)

Customer Success Story

August 12, 2022

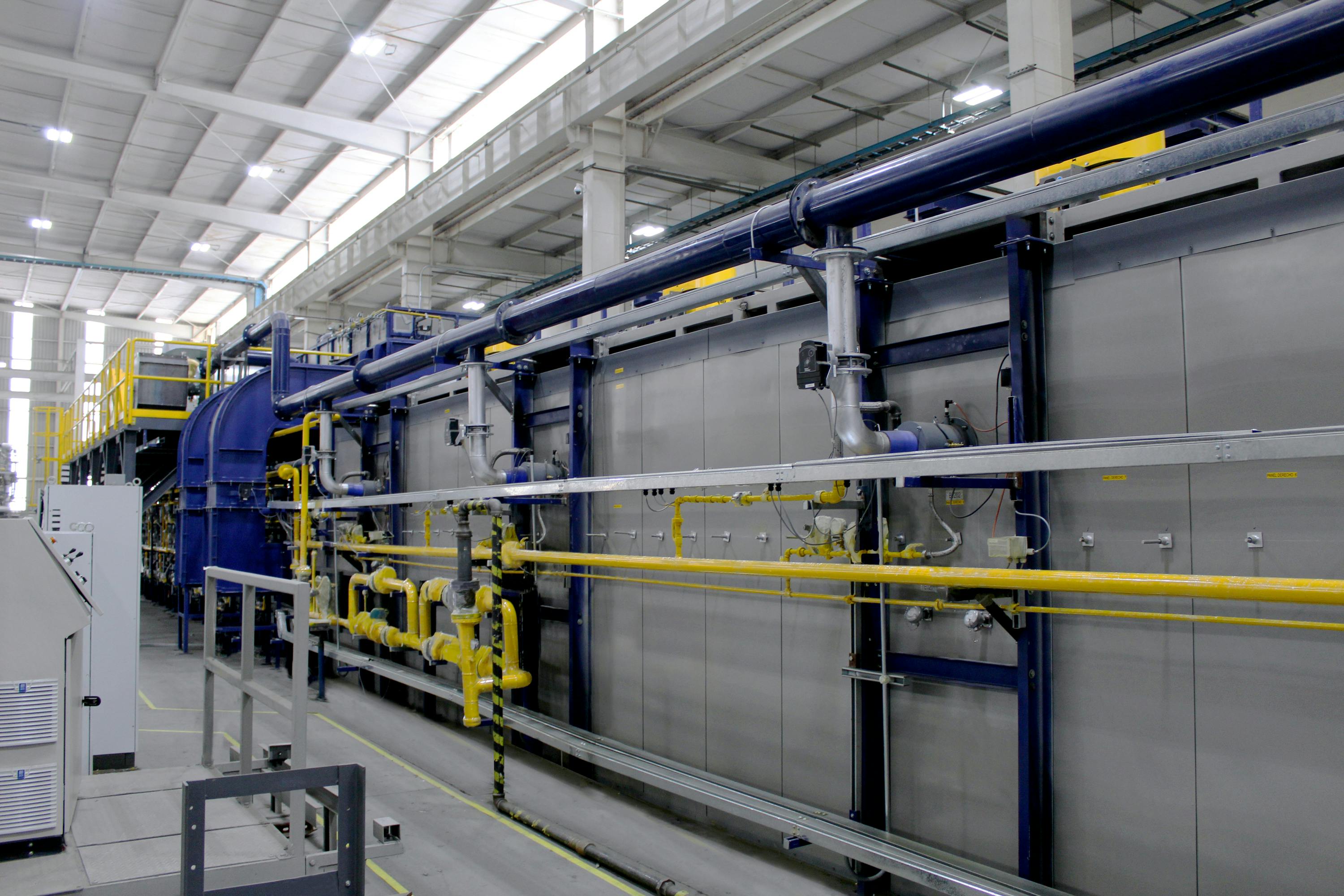

In a major, high-value project – the second at this particular plant in Mexico – NUTEC Bickley will supply a 125m-long tunnel kiln to one of the world’s leading advanced ceramics manufacturers.

Articles & Editorials

By Francois Desjardins

USA/Canada Sales Manager, NUTEC Bickley

April 8, 2024

Achieve optimal results in heat treating aluminum. Learn about different furnace configurations and their ideal use cases.