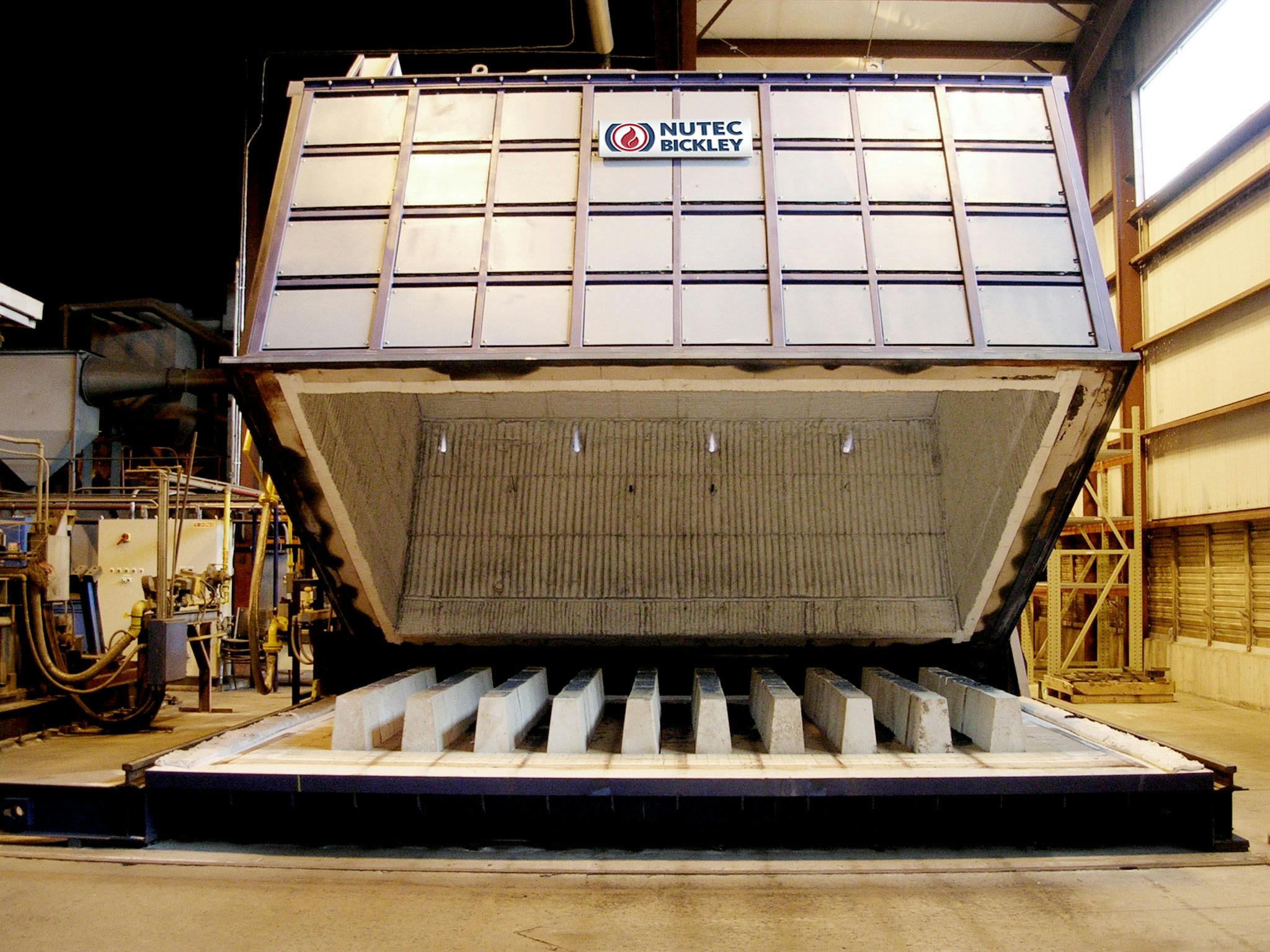

NUTEC Bickley's tip-up furnaces provide a flexible operational process by allowing the high temperature process (austenitizing) and the low temperature process (tempering) to be executed in the same furnace.

Tip-up furnaces are commonly used in intermittent (or batch) processes. Here, the product is placed directly into the furnace by means of a front-loading mechanism, usually via a forklift or using a handling device.

The process of lifting or opening the furnace is usually performed using hydraulic cylinders to ensure an efficient mechanical movement of the unit.